In the fast-paced world of electronics manufacturing, precision is everything. A single micron off in a component can lead to costly failures, delays, or even product recalls. That's where electronics precision machining comes in—leveraging advanced CNC technology to craft intricate, reliable parts that power everything from smartphones to medical devices. At Huihuan, we specialize in delivering high-precision CNC machining solutions tailored for the electronics industry, ensuring your designs translate seamlessly from prototype to production.

Whether you're developing next-gen wearables or robust industrial controls, this guide explores how CNC machining revolutionizes electronics fabrication. We'll dive into the processes, benefits, applications, material selection, and why partnering with a trusted expert like Huihuan can supercharge your projects. Ready to elevate your manufacturing game? Let's get started!

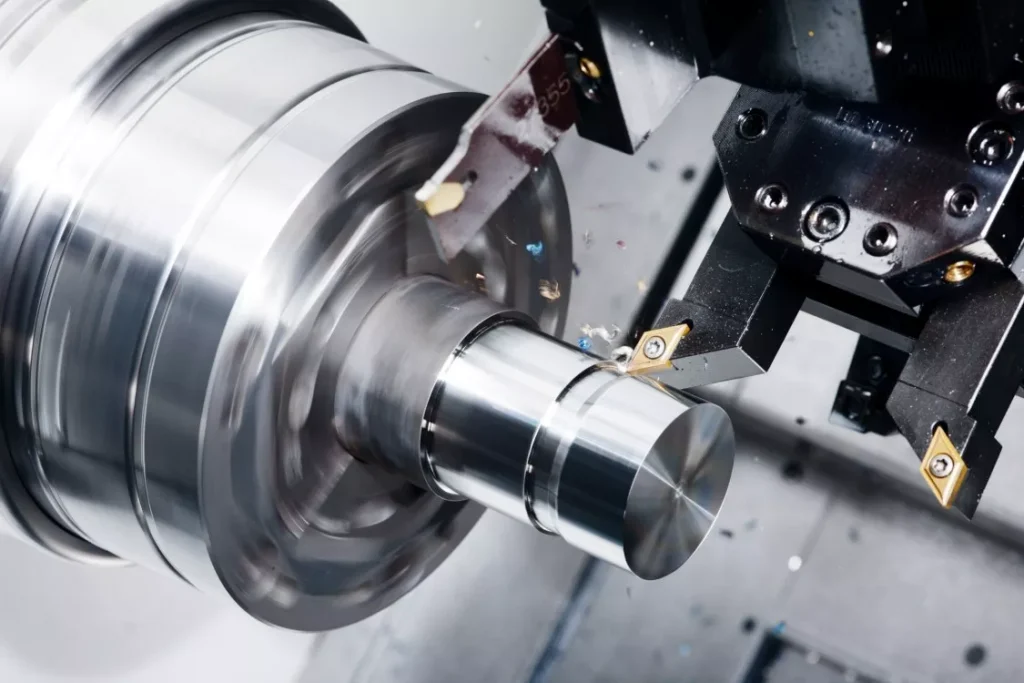

Electronics precision machining refers to the use of computer numerical control (CNC) systems to fabricate ultra-accurate components for electronic devices. Unlike traditional methods, CNC machining automates the process with programmed instructions, achieving tolerances as tight as ±0.001 mm—critical for parts where even the slightest imperfection can disrupt signal integrity or thermal performance.

At its core, this involves operations like milling, turning, drilling, and grinding on materials ranging from metals to advanced polymers. For electronics, the focus is on miniaturization: think micro-holes in PCBs, custom enclosures for sensors, or intricate connectors for IoT devices. Huihuan's CNC expertise ensures every part meets exact specifications, reducing waste and accelerating time-to-market.

Why does this matter? In an industry where reliability is non-negotiable, precision machining minimizes defects and supports scalable production. Curious about the tech? Check out our CNC capabilities.

| Aspect | Traditional Machining | CNC Precision Machining (Huihuan) |

|---|---|---|

| Accuracy | ±0.1 mm (manual variability) | ±0.001 mm (automated precision) |

| Production Speed | Slow setup for small batches | Rapid prototyping to high-volume runs |

| Material Waste | High due to human error | Minimal with optimized tool paths |

| Customization | Limited by operator skill | Infinite via CAD/CAM software |

CNC machining isn't just a tool; it's a game-changer for electronics. Its ability to handle complex geometries with repeatability makes it indispensable for sectors demanding zero tolerance for error. Here's why leading brands trust CNC—and why Huihuan's advanced setups deliver superior results:

Electronics components like RF shields or LED housings require exacting standards. Huihuan's multi-axis CNC machines (up to 5-axis) handle intricate features with ease, ensuring tolerances down to ±0.005 mm. This is vital for high-frequency applications in telecom or aerospace.

Program once, produce endlessly. CNC eliminates human variability, guaranteeing identical parts batch after batch—perfect for mass-producing connectors or circuit frames.

From concept to shelf in days, not weeks. Our digital workflows allow quick iterations, while high-speed spindles keep production humming without sacrificing quality.

CNC excels with everything from conductive aluminum to insulating PEEK. No need for multiple vendors—Huihuan processes it all under one roof.

Deburred edges and smooth surfaces prevent shorts or contamination. Post-machining cleaning ensures parts are assembly-ready.

For a visual demo, watch this short video on Huihuan's CNC process for electronics (embedded from our channel—see how we turn raw stock into precision masterpieces in under 2 minutes).

CNC's versatility shines across electronics subsectors. At Huihuan, we've machined parts for everything from consumer gadgets to mission-critical systems. Here's a spotlight on top uses:

Smartphones, smartwatches, and laptops demand sleek, lightweight casings. CNC crafts custom brackets and heat dissipators that fit like a glove, enhancing device aesthetics and performance.

Routers and 5G antennas need durable, weather-resistant housings. Our CNC services produce aluminum enclosures that withstand -40°C to 85°C extremes.

Chip carriers and robotic end-effectors require micron-level accuracy. CNC ensures vibration-free stability for high-throughput fabs.

Biocompatible titanium implants and diagnostic enclosures? CNC delivers sterile, precise components compliant with ISO 13485 standards.

EV battery mounts and avionics sensors endure harsh conditions. Huihuan's expertise in high-strength alloys guarantees reliability.

| Application Area | Common CNC Parts | Key Benefit from Huihuan |

|---|---|---|

| Consumer | Enclosures, Connectors | Lightweight, aesthetic finishes |

| Telecom | Antenna Housings, Brackets | Corrosion-resistant durability |

| Medical | Sensor Mounts, Probes | Biocompatible precision |

| Automotive | Control Panels, Wiring Harnesses | Vibration-proof assembly |

Material choice can make or break your project's success. At Huihuan, our engineers guide you through options based on conductivity, thermal properties, and machinability. Key considerations:

Conductivity Needs: Copper or aluminum for heat sinks; PEEK for insulators.

Thermal Resistance: Ceramics for high-heat zones; polymers for lightweight cooling.

Durability: Stainless steel for rugged industrial parts; ABS for cost-effective prototypes.

Weight Optimization: Aluminum alloys reduce bulk in portables.

Corrosion Resistance: Titanium or coated plastics for harsh environments.

Machinability and Cost: Prioritize aluminum for fast, affordable runs.

In a crowded market, what sets Huihuan apart? We're not just machinists—we're your strategic ally in electronics innovation. With over a decade of experience, ISO 9001 certification, and a fleet of cutting-edge CNC equipment, we deliver:

Proven Expertise: Specialized in electronics, from PCBs to enclosures.

Advanced Tech: 5-axis mills, Swiss lathes, and CMM inspection for ±0.001 mm accuracy.

Rigorous QC: 100% inspection with automated metrology—zero defects guaranteed.

Material Mastery: In-house sourcing of 50+ alloys and polymers.

Flexible Support: Prototypes in 24 hours; scalable to millions of units.

Seamless Communication: Real-time updates via our client portal.

Don't just take our word—request a free quote today and see how we can streamline your supply chain. Global shipping, engineering consultations, and on-time delivery are standard.

Electronics precision machining via CNC isn't optional—it's essential for building reliable, high-performance devices. From pinpoint accuracy to versatile applications, it empowers innovation while cutting costs and timelines. Pair that with smart material choices and a partner like Huihuan, and you're set for success.

Ready to prototype your next big idea? Visit Huihuan's electronics machining services for expert guidance, instant quotes, and unmatched quality. Let's machine the future—together!