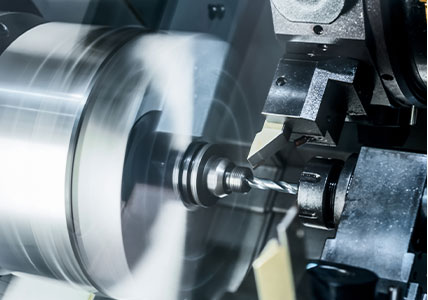

CNC Machining is a technology to control mechanical motion and working processes with digital information. It is the basic technology of the modern manufacturing industry, which integrates traditional machinery manufacturing technology, computer technology, modern control technology, sensing and detection technology, network communication technology, AI CNC technology and optoelectromechanical technology. It has the characteristics of high precision, high efficiency, flexible automation, etc. It plays an important role in realizing flexible automation, integration and intelligence in the manufacturing industry. Numerical control applications are reflected in many aspects and high fields.

1. CNC Machining Application In Manufacturing Industry

The machinery manufacturing industry is the earliest application of numerical control technology industry, it is responsible for the national economy industries to provide advanced equipment.

2. CNC Machining Applications In The Information Industry

In the information industry, from computers to network, mobile communication, telemetry, remote control and other equipment, all need to use super-precision technology, nanotechnology-based manufacturing equipment, such as lead bonding machines, wafer bonding machines and lithography machines for chip manufacturing, the control of this equipment need to use numerical control technology.

3. CNC Machining Applications In The Medical Equipment Industry

In the medical industry, many modern medical diagnosis and treatment equipment have adopted numerical control technology with custom precision machined parts, such as CT diagnostic instrument, whole body knife treatment machines and minimally invasive surgery robots based on visual guidance.

4. CNC Machining Application Of Military Equipment

Servo motion control technology is widely used in many modern military equipment with CNC automation parts, such as automatic aiming control of artillery, tracking control of radar and automatic tracking control of missile.

The popularity of numerical control applications has the following advantages:

1. Greatly reduce the number of tooling, processing complex shape parts do not need complex tooling. If you want to change the shape and size of the parts, you only need to modify the parts processing program, suitable for new product development and modification.

2. Stable machining quality, high machining precision, and high repeat precision, to meet the requirements of aircraft processing.

3. The production efficiency is higher under the condition of multiple varieties and small batch production, which can reduce the time of production preparation, machine tool adjustment, and process inspection, and reduce the cutting time due to the use of optimal cutting quantity.

4. It can process complex surface which is difficult to be processed by conventional methods and even some parts that cannot be observed