Keep the following points in mind when positioning multiple components.

One or more components can be added for positioning even when the positioning tool is active. The added component will immediately get the transformations shared by the other components.

If 2 or more components are selected for positioning, you cannot deselect any of them until they have been positioned.

Use the dragger's handles to move and reposition multiple components as a single unit. While dragging the linear handle, fix the components to a geometric reference and constrain them.

If you add one or more components to a group of multiple components already positioned, any constraints previously applied when positioning the components are clear.

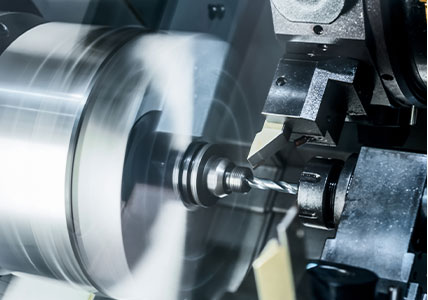

[1] Method of using a positioning pin The workpiece is positioned using a cylindrical or tapered positioning pin.

[2] Method of adjusting the positioning surface (point) Allows the use of adjustable positioning pins to adjust the orientation.

[3] Method of adjusting the position of the workpiece to a fixed datum plane Press the face of the workpiece onto the datum plane for positioning.

[4] Centering Positioning a cylindrical workpiece to its center.

[5] Indexing Positioning the workpiece at a specified distance in a straight line.

[6] Method using V-slot Position the cylindrical workpiece along the V-slot in the longitudinal direction.

What is positioning refers to the highly accurate maintenance of the positional relationship between two objects. any one object. As a basis for positioning... (e.g., positioning fixture) Another object. The object to be positioned to the positioning base... (e.g.: workpiece) To place two objects in a configuration where their positional relationship is set in an efficient manner (refer to [Figure 1]).

Example.

1. Place the two dowels for positioning as far apart as possible

2. Set the dowels in a symmetrical position

Select the positioning method according to the operation to be performed (manual, automatic, prototyping, mass production, etc.) and the characteristics of the workpiece (accuracy level, appearance quality level, material, etc.).

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.