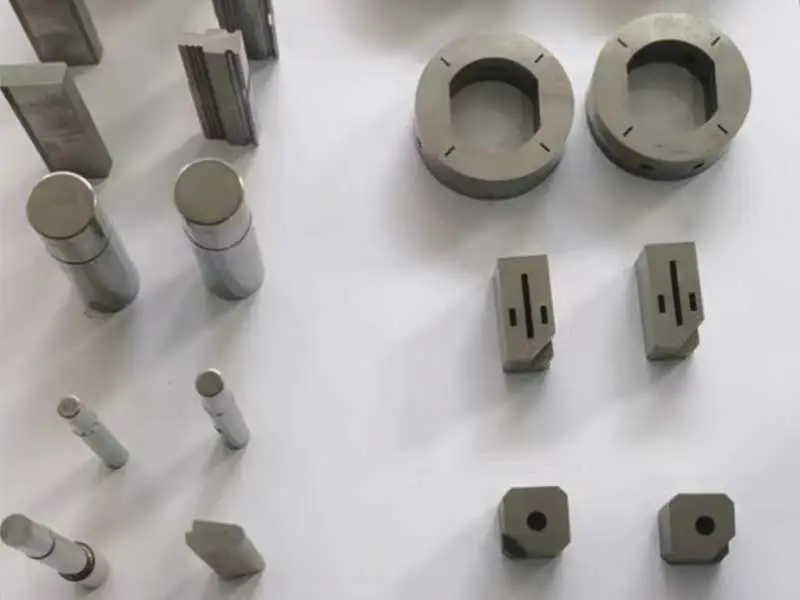

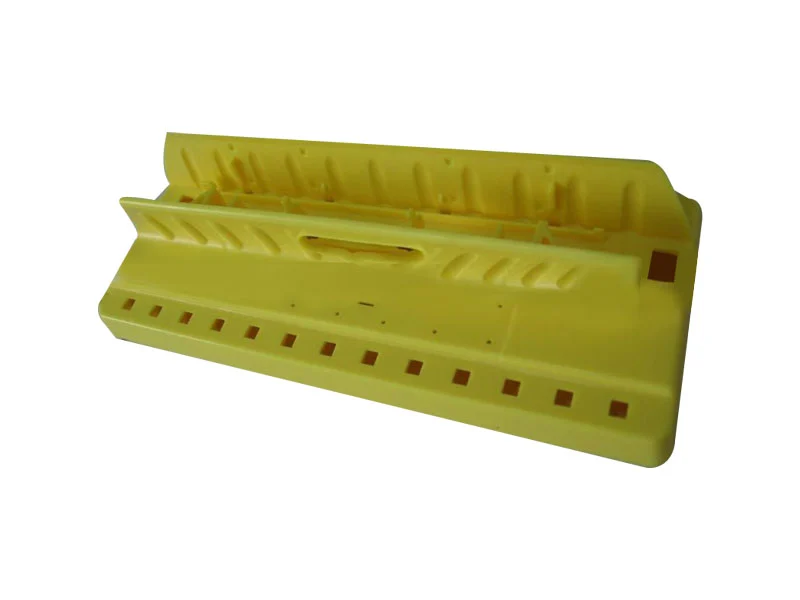

For example, the unloading plate, concave die or convex die fixing plate hole should be processed according to the drawing of the part, and then the upper and lower die base guide pillar and guide bushing hole should be processed according to the reference part, and the fixing hole of the guide bushing hole should be processed directly according to the reference. By classifying and grouping the shape structure and process characteristics of the precision mechanical parts to be processed, forming a complete set of process flow, the core principle of which is to centralize the processing of the parts by adjusting the fixture, the same group of parts and tools. The use of this method can change the traditional single machine tool, single process and single workpiece processing method into a multi-process, multi-workpiece centralized processing method, which can achieve a significant reduction in the number of clamping, and may improve to a certain extent the precision of the position of each processing surface of precision mechanical parts, and accordingly improve its assembly accuracy, which is of great significance for improving production efficiency, controlling costs and increasing efficiency.