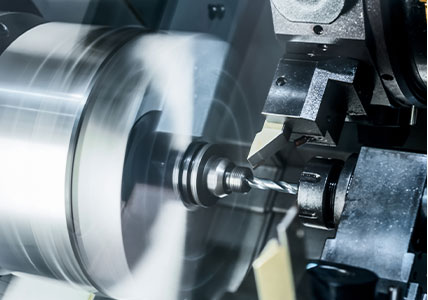

A CNC lathe can be used to machine complex turned shapes. Milling is the process of fixing the blank and using a high-speed rotating milling cutter to cut out the required shape and features. Traditional milling is mostly used for simple external features such as milling contours and slots, while CNC milling can be used to machine complex shapes and features. Boring and milling machining centers can perform three-axis or multi-axis boring and milling machining, used for machining molds, jigs, tire tools, thin-walled complex surfaces, artificial prosthetics, blades, etc. When choosing CNC milling services, one should fully utilize the advantages and key roles of CNC milling machines.

CNC milling services are a machining process of CNC automation parts that uses rotating cutting tools to remove excess material from a block until the desired custom shape is formed. In addition, CNC milling services can produce very complex parts while meeting strict tolerance requirements. Through continuous improvement and refinement, CNC milling services can manufacture precision parts that meet the stringent requirements of today's demanding industries.

CNC milling services are mainly used for subtractive manufacturing. The part to be milled is fixed in the CNC turning fixture on the CNC worktable, and then the original material is machined using the X, Y, and Z axes of the CNC milling machine. The cutting tool spindle rotates at a high speed to cut the material, thus achieving the desired part. When combined with advanced computer-aided design software, CNC milling services can create outputs that manual operation machines cannot replicate, regardless of the engineer's skill level.

CNC milling services have the characteristics of flexibility and diversity in application and can be used for various complex parts with different structures. On a CNC milling machine, drilling, boring, milling flat surfaces, milling end faces, tapping, and other processes can be completed. In addition, CNC milling services have high accuracy and repeatability, meeting the requirements of high-quality machining. CNC milling services effectively avoid human operational errors and maintain consistent part dimensions in small batch production.

CNC milling machines also have the functions of drilling and boring machines. In multi-variety small-batch production lines, the use of CNC milling services centralizes the machining process, which improves production efficiency and reduces the error rate of part clamping. In addition, CNC milling services also have the functions of rapid feed, rapid retract, and rapid positioning of the tool changer, thereby reducing maneuvering time. CNC milling services can also machine complex profiles that are difficult to machine on CNC lathes, even planar and spatial surface contours of parts. This is because CNC milling services have the characteristics of multiple feed coordinates and feed axis linkage.