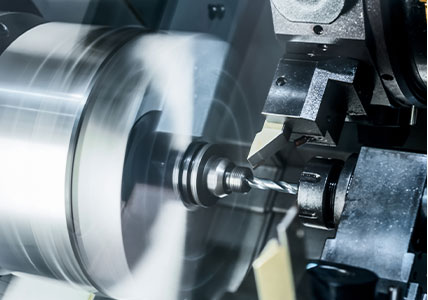

Steel is the most widely used and recycled metal material on the planet. From stainless and high-temperature steels to flat carbon products, steel in various forms and alloys offers a wide range of properties to meet a wide range of applications. For these reasons, as well as the combination of the metal's high strength and relatively low production costs, stainless steel is now used in countless stainless steel products, such as stainless steel CNC machining parts.

1. Machining hardness leads to faster tool wear and dragging difficulties.

2. The low thermal conductivity causes plastic deformation of the thinning edge and tool wear.

3. The inverted tumor is easy to form a small pattern on the mucus, resulting in a poor surface of stainless steel cnc machining parts.

4. The chemical relationship between the tool and the material to be machined leads to machining hardening and low thermal conductivity of the material to be machined, not only easy to abrade but also prone to cutting edge and abnormal rupture

1. Use tools with high thermal conductivity.

2. Sharp cutting edge line: chip groove inserts are wider to reduce the cutting pressure, so you can control the resistance.

3. Proper cutting conditions: inappropriate processing conditions can reduce the life of stainless steel cnc turning parts.

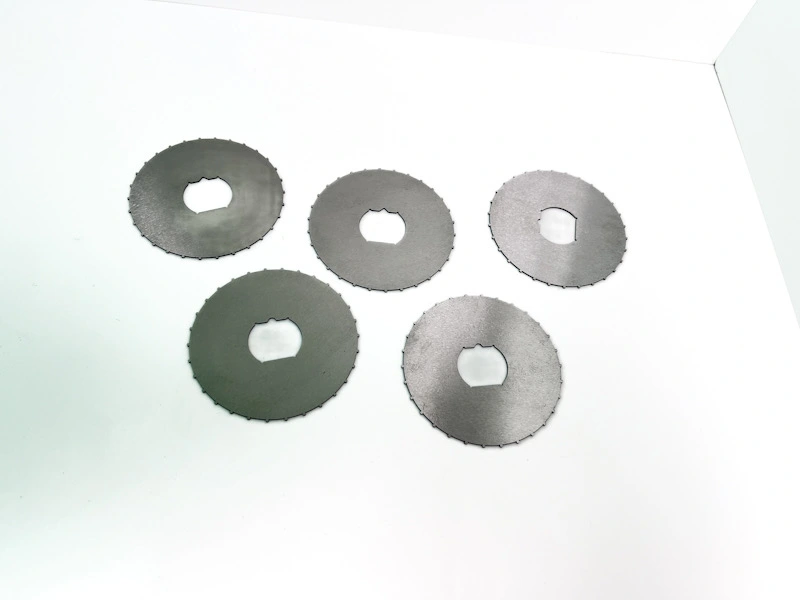

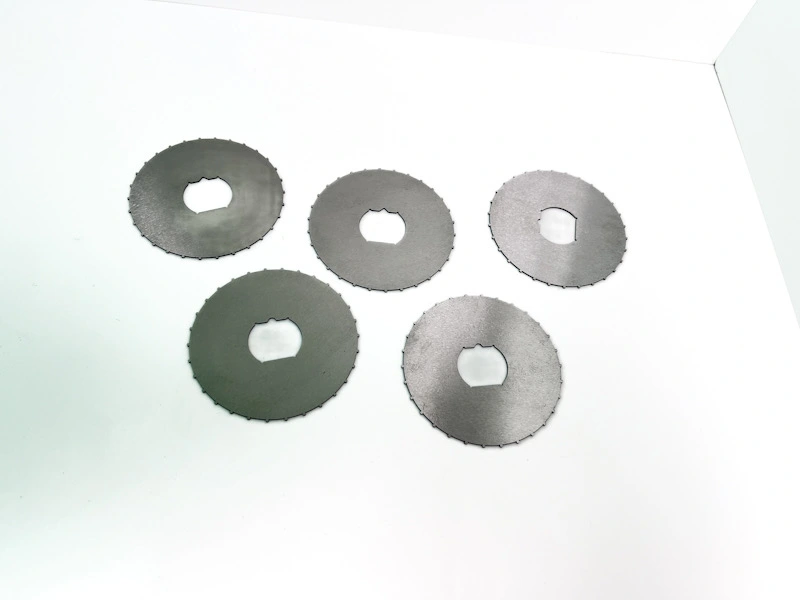

4. Choose the right tool: stainless steel precision parts should have excellent toughness and cutting-edge strength and the clamping strength of the coating is also relatively high.

1. Tool material selection. Because of the CNC machining of the stainless steel part's cutting force, and high cutting temperature, the tool material should try to choose high strength and good thermal conductivity carbide. The roughness value should be small when sharpening the front tool surface. In order to avoid the phenomenon of chip sticking, the front and rear tool faces should be carefully sharpened to ensure a small roughness value, thus reducing the chip flow resistance and avoiding chip sticking.

2. The cutting edge of the stainless steel cnc turning parts should be kept sharp. The cutting edge of the cnc machining stainless steel parts should be kept sharp to reduce machining hardening, and the feed and back draft should not be too small to prevent the tool from cutting into the hardened layer and affecting the tool's life.

3. Pay attention to the grinding of the chip breaker groove. Due to the toughness of chips of stainless steel precision parts, the chip breaker groove on the front face of the tool should be resharpened appropriately, so that the cutting process is convenient for chip breaking, chip holding and chip removal.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.