Bead Blasting, is dry sandblasting with abrasives can be steel sand, alumina, quartz sand, silicon carbide, etc., but the most applied is quartz sand, according to the parts material, surface state and processing requirements, can choose different substances of abrasives.

Sandblasting effect is mainly determined by the parts material and sandblasting abrasive. According to the different materials of the parts, sandblasting abrasives can range from metal abrasives with strong effects to resin abrasives with soft effects, while dry sandblasting and liquid sandblasting are also key factors to consider.

Production efficiency to determine the type of equipment. According to the processing capacity to choose automatic sandblasting production line, semi-automatic sandblasting equipment, press-in sandblasting machine, inhalation sandblasting machine.

The size of the workpiece to determine the equipment specifications. Select the cabin size according to the workpiece size so that there is enough space to finish the processing work.

Compressed air requirements, determine the capacity of air compressor according to the equipment specifications, and leave 20% margin to protect the service life of air compressor.

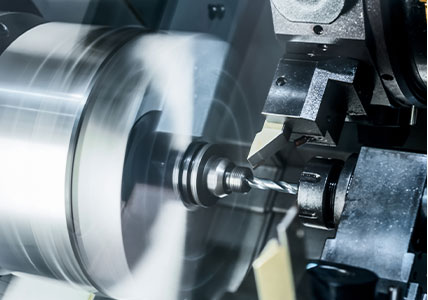

Sandblasting is the process of cleaning and roughening the surface of the substrate by the impact of high speed sand flow. It is powered by compressed air to form a high-speed spray beam, which drives the sand material (diamond sand, ceramic sand, stainless steel sand, glass sand, etc.) to spray onto the surface of the work piece to improve the cleanliness and roughness of the work piece surface, thus improving the mechanical properties. The role of sandblasting is not only to improve the mechanical properties, but also to remove surface dirt and rust, and the oxide film on the surface of aluminum profile can be removed by sandblasting treatment. As a result of sandblasting treatment, the surface becomes rough and can be used as a pretreatment process for spraying and oxidation to increase the adhesion performance of the coating. Sandblasting process can also remove the surface burr of the work piece and improve the safety of the later processing, and the metal surface is matte metallic color after sandblasting, which is very beautiful.

The scope of application of sandblasting includes.

1) Work pieces that need to be sprayed, plated or oxidized can use sandblasting as a pretreatment process

2, work pieces that need to improve mechanical properties

3, work pieces whose surfaces need to be beautified or need to be cleaned of burrs.

4、Castings and heat treatment work piece rough surface cleaning and polishing.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.