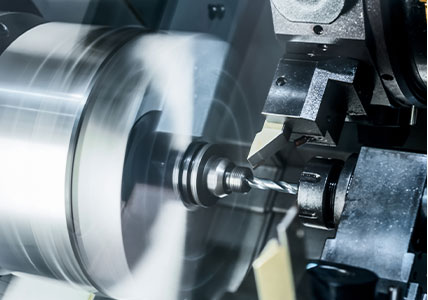

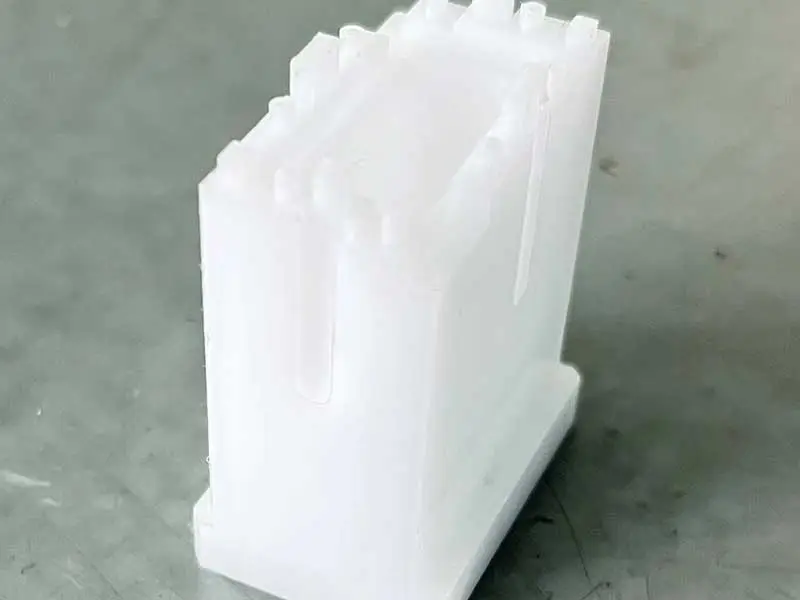

CNC Machining Parts are components produced by CNC (computer numerical control) machining. CNC machining is a manufacturing process primarily used for producing precision metal and plastic components. The process involves using a computer to control a machine tool, such as a milling machine, lathe, or router, to produce the desired part. CNC machined parts are widely used in a variety of industries, including aerospace, automotive, medical, and defense.

How to reduce/save CNC machining costs

Type of material

The size of the material

Type of CNC machine

The complexity of the part geometry

Delivery time frame required for production runs

The difference between rounded and chamfered corners

mechanical engineering drawing and design

Rationalizability of machining processe

CNC Machining Parts are components produced by CNC (computer numerical control) machining. CNC machining is a manufacturing process primarily used for producing precision metal and plastic components. The process involves using a computer to control a machine tool, such as a milling machine, lathe, or router, to produce the desired part. CNC machined parts are widely used in a variety of industries, including aerospace, automotive, medical, and defense.

How to reduce/save CNC machining costs

Type of material

The size of the material

Type of CNC machine

The complexity of the part geometry

Delivery time frame required for production runs

The difference between rounded and chamfered corners

mechanical engineering drawing and design

Rationalizability of machining processe

Name | Description |

Max Dimensions | 1600mm x 1200mm x 900mm |

Tolerance | Linear dimension: +/-0.025 mm Hole diameters (not reamed): +/- 0.025 mm |

Burrs And Chamfers | Deburring by default, chamfering according to your requirements |

Drawing Format | 2D Drawing: PDF/JPG/DWG 3D Drawing: STP/STEP/IGS/IGES/STL |

Surface Finishing | Powder coated, anodizing, bead blasting, black oxide, heat treatment |

CNC machining manufactures custom parts for a variety of applications from rapid prototyping to volume production. Here are some of the most common applications for CNC machined parts:

1. Artificial Intelligence

2. New energy industry

3. Automation Industry

4. Transportation industry

5. Shaft assemblies

6. Spindle housing hub

7. Valve body

8. ball joint

9. Suspension arm

10. Rail and switch gear

11. Thermal control

12. Fasteners

13. Medical equipment

14.Internet Communication

15. Molds

16. ratchet gears

17. Smart Home

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.