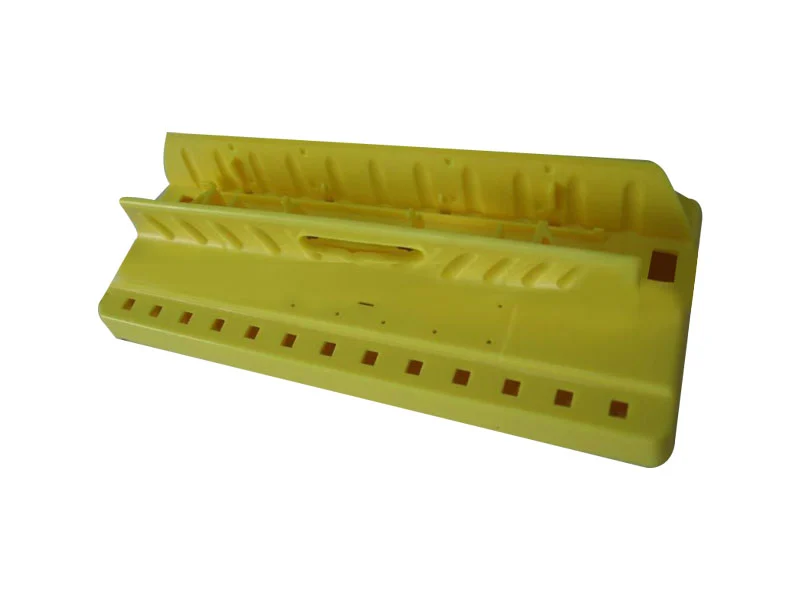

Single-section shooting tip, double-section shooting tip, double-section shooting tip, flat tip, flat tip, positioning post, plastic mold guide bushing, straight bushing, center post bushing, plastic mold guide bushing, straight bushing, center bracket bushing, positioning post, square type auxiliary, three-dimensional positioning block group guide position auxiliary, A, B, C type filling nozzle, fixed ring A, B type, standard type mechanical switch device, square type auxiliary, small water spout standard special injection spout bushing, large water spout standard special injection spout bushing, Mold date indication device, resin switchers, water stop pins, finished tips for plastic molds, pen cores, pen tubes, small puller C type, diagonal support tips, puller tips, plastic mold guide posts, pullers, return pins, springs, thimbles, sizers, garbage pins, etc.

Generally speaking, there are seven parts:

1. Pouring system;

2. Molding parts, i.e. cavities;

3. Exhaust structure;

4. Push-out mechanism;

5. Side core extraction mechanism;

6. Mould closing guide mechanism;

7. Heating and cooling system.

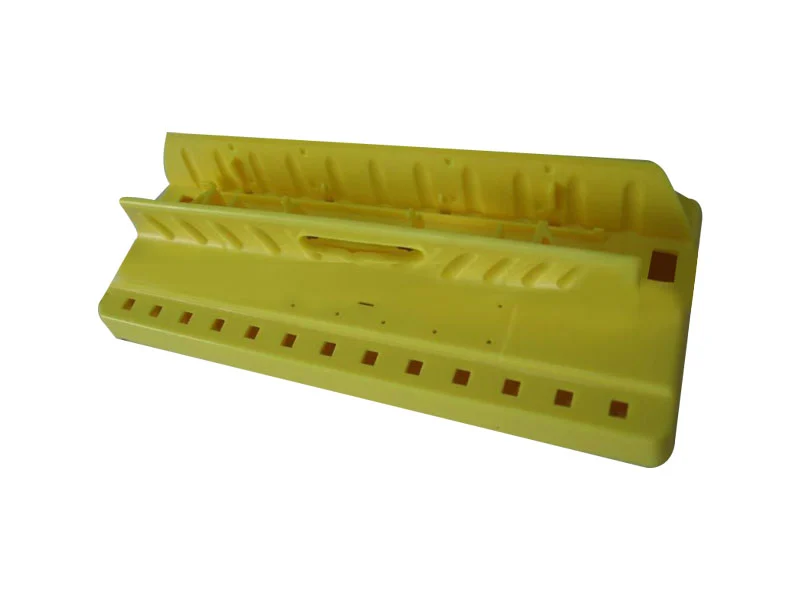

For precision plastic mold, in the role of long-term cyclic force, if the quality of the product is not good is likely to produce fatigue fracture problems. But therefore this requires high-quality precision plastic mold that can be technically perfect, improve their own fatigue fracture performance

Many times the precision plastic mold also needs a high-temperature environment for operation, if the product does not meet the standard, then will certainly be in the use of process of loss, and even trigger the story.

In addition to the above need to have the content, as a precision plastic mold, the best also needs to have cold and heat fatigue resistance, corrosion resistance and other properties, with these properties it can adapt to a more complex working environment, in order to more permanent normal operation.

A qualified precision plastic mold needs to choose a malleable, annealing process and cutting processability of the material for production, so as to ensure that the product quality is more high-end. Secondly, some molds also need to be used in relatively harsh environments, so this requires you must choose to withstand the impact load, not to brittle fracture of the material, only such strength and toughness to ensure that in the complex environment is still normal function.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.