Liquid silicone rubber (LSR) molding is a form of injection molding. The production process of the rapid prototype rubber parts is that the liquid silicone rubber is first injected into the mold, then the liquid is thermally cured, cooled and removed from the mold. When prototyping rubber parts, compression molding uses uncured rubber that has been preformed into a controlled shape, such as a disc. The mold surrounds the part and compresses it between two plates under high pressure. The high temperature and pressure vulcanize the rubber to cure the part. Pins automatically eject the part from the mold, thereby speeding up production.

Huihuan is a distinguished specialist in the realm of rubber rapid prototyping. With our profound expertise and cutting-edge technology, we excel in swiftly transforming concepts into tangible rapid prototyping silicone rubber parts, facilitating innovation and efficiency for our valued clients.

1. The application of rapid rubber part prototyping technology in the process of new product modeling and design has established a new product development model for the design and development of industrial products.

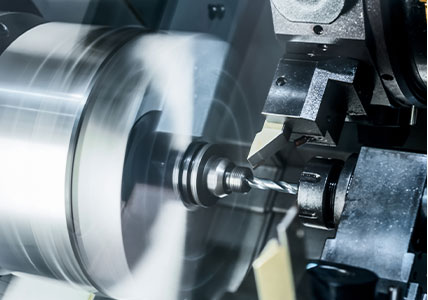

2. In the field of mechanical manufacturing applications due to the characteristics of RPM technology itself, making it in the field of mechanical manufacturing, access to a wide range of applications, mostly for the manufacture of single-piece, small-batch metal parts manufacturing. PM technology for direct molding, low cost, short cycle time.

3. Rapid mold manufacturing traditional mold production time is long and high cost. The combination of technology of rapid prototyping silicone rubber parts and traditional mold manufacturing technology can greatly shorten the development cycle of mold manufacturing and improve productivity, which is an effective way to solve the weak link between mold design and manufacturing.

4. Application in the medical field In recent years, there are more research on the application of RPM technology in the medical field. Based on medical image data, the use of RPM technology to make human organ models has great application value for surgical operations.

5. Application in the field of aerospace technology In the field of aerospace, the model used in aerodynamic ground simulation experiments has a complex shape, high precision requirements and streamlined characteristics, using RPM technology, according to the CAD model, the solid model is automatically completed by RPM equipment, which can well ensure the quality of the model.

6. Application in the home appliance industry At present, the rapid rubber part prototyping system has been popularized and applied to a large extent in the domestic home appliance industry, making many home appliance enterprises take the lead in the country.

Rapid rubber part prototyping technology is a computer-controlled technology based on the principle of discrete and stacking, using different methods of stacking materials to finally complete the forming and manufacturing of parts.

1. From the perspective of forming, the part can be regarded as a superposition of "points" or "surfaces". Discrete from the CAD electronic model to get the "point" or "surface" geometric information, and then combined with the forming process parameters, control the material regularly and accurately from point to surface, from surface to body stacking parts.

2. From the manufacturing point of view, it generates three-dimensional geometric information of prototype rubber parts according to CAD modeling, controls the multidimensional system, and forms prototypes or prototype silicone rubber parts by stacking materials layer by layer through laser beam or other methods.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.