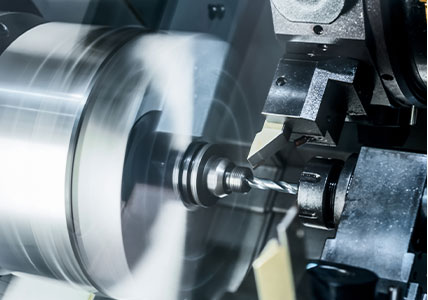

CNC machining is a widely used and reliable manufacturing process that can be applied to various applications. Whether for prototyping or production, metal or plastic, CNC machining is an essential tool for engineers in manufacturing, automotive, aerospace, pharmaceutical, consumer goods, and many other industries. So when should CNC machining be chosen?

In the direct battle between CNC machining and 3D printing, the former manufacturing process offers outstanding precision and the ability to meet strict tolerances. In fact, very few manufacturing technologies come close to numerical control in terms of accuracy. This means that even in critical situations where there are reasons to choose numerical control and reasons to choose another manufacturing process, numerical control can have an advantage when precision is of utmost importance. In general, this may be a key consideration in the final production process, if not as important in the prototyping process. CNC machining can achieve tolerances as low as 0.025 millimeters - stricter than any additive manufacturing technology - and should be preferred if tolerances need to be less than about 0.2 millimeters.

Due to the fact that parts made by CNC machining are cut from solid billets, they have excellent mechanical properties. They are also strong in all three dimensions - unlike 3D printed parts, which are inherently weaker in one axis due to their layered structure. Machined parts are suitable for even the most demanding applications, unlike all parts manufactured using 3D printing or molded parts with fragile connections. Therefore, when part performance is more important than budget or turnaround time, numerical control is often a better choice than alternatives.

For simple solid shapes, there are very few reasons to deviate from CNC machining (or, depending on material and unit quantity, injection molding). This is due to the precision and superior mechanical properties mentioned above. Additive manufacturing is the primary alternative to CNC machining and is most valuable when complex geometries with difficult-to-trace cutting tools are involved. However, simple machined cubes with minimal surface features generally have better mechanical properties than 3D printed cubes made from similar materials. If a part can be manufactured using a numerical control machine, it is likely that it should be.