About half a century ago, the responsibility for producing high quality and precision manufactured goods fell on human engineers. While modern manufacturing still requires this level of skill and expertise, the numerous advantages of CNC milling services compared to more traditional techniques have made computerized manufacturing much more common. CNC machining is especially important in industries such as aerospace, automotive, shipbuilding, and medical, and can be used to perform various complex processes such as milling, grinding, turning, and stamping. This technology has completely transformed the industry and has played a significant role in the revival of the manufacturing sector in the UK in recent years.

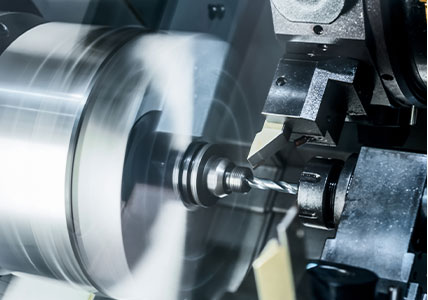

CNC milling services (also known as computer numerical control milling services) is a manufacturing method that utilizes pre-programmed software to control machining tools. Digital instructions are first inputted into the computer, which then automatically operates the machine to create precise components that match the specified specifications. This manufacturing method is slightly different from CNC turning, which involves rotating the raw material around a stationary cutting tool at high speeds to shape the material correctly. On the other hand, CNC milling services keep the material stationary while the tool rotates.

Compared to conventional machining, CNC milling services have the characteristics of high machining precision, the ability to process complex shapes, and a wide range of applications. Based on the characteristics of CNC milling services, we can generally understand that the types of parts suitable for CNC milling services mainly include the following.

Parts with complex structures such as curved contours or surfaces: Parts with planar curved contours, where the part has complex inner and outer contours and the machining surface is parallel or perpendicular to the horizontal plane. In three-dimensional coordinate space, the surface of the part is usually a point variation on the surface. It is usually designed based on a mathematical model. During the machining process, the milling cutter always maintains point contact with the machining surface. Three-coordinate CNC milling services are usually used for machining parts with curved surfaces, as programming is required with the assistance of a CNC system.

Parts with structures that are difficult to machine with conventional milling: For parts that are difficult to observe and control in terms of dimensions, marking, and inspection, conventional milling machines do not have the assistance of a CNC system for machining. Therefore, CNC milling machines are very suitable for these parts.

Parts that require precision and accuracy that cannot be achieved with conventional milling: Due to the errors caused by human factors in conventional milling, it is difficult to guarantee the dimensional accuracy, shape accuracy, and surface roughness of the parts. Therefore, CNC milling machines are needed for machining parts that require high precision.