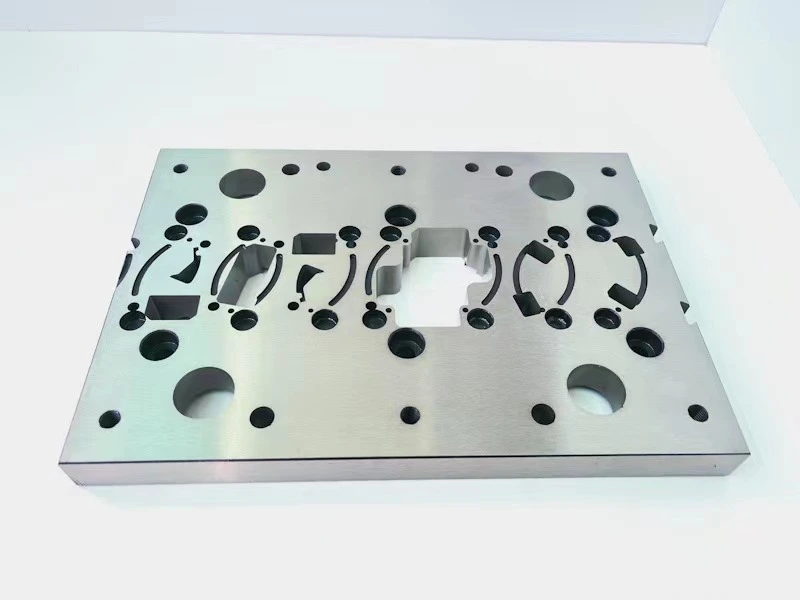

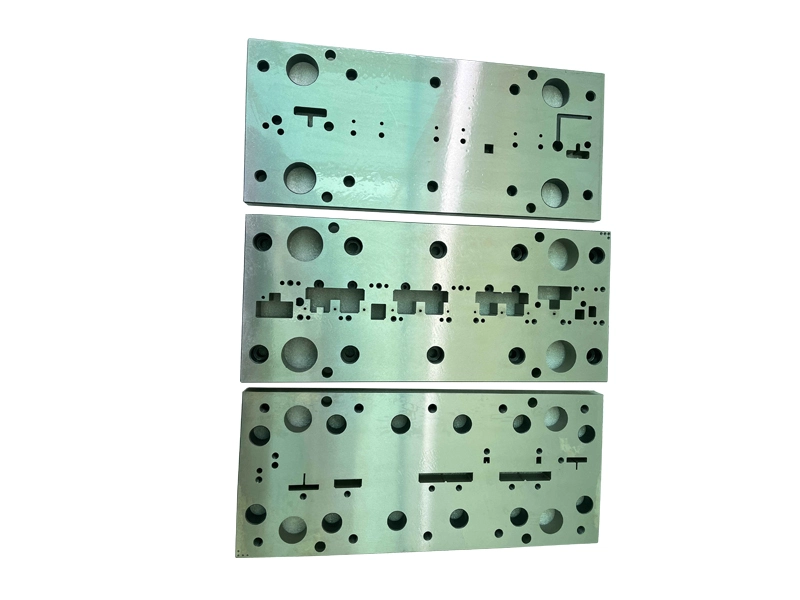

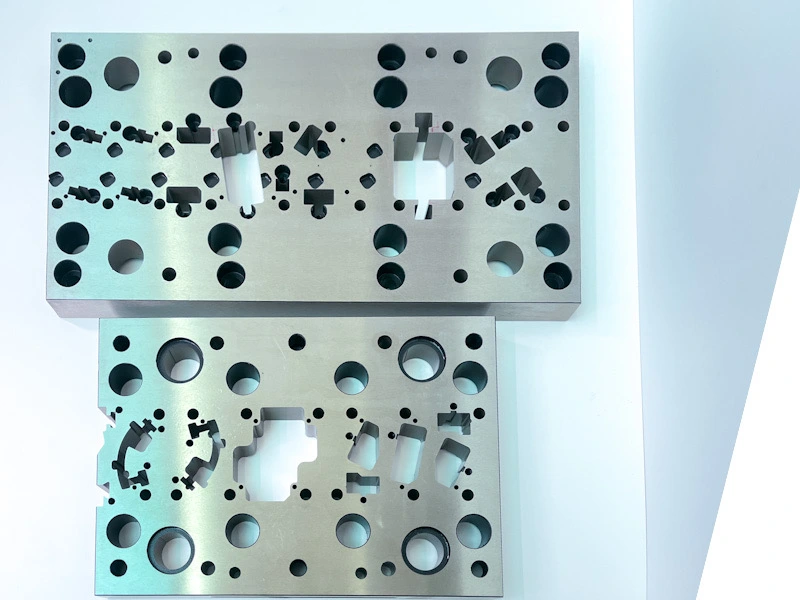

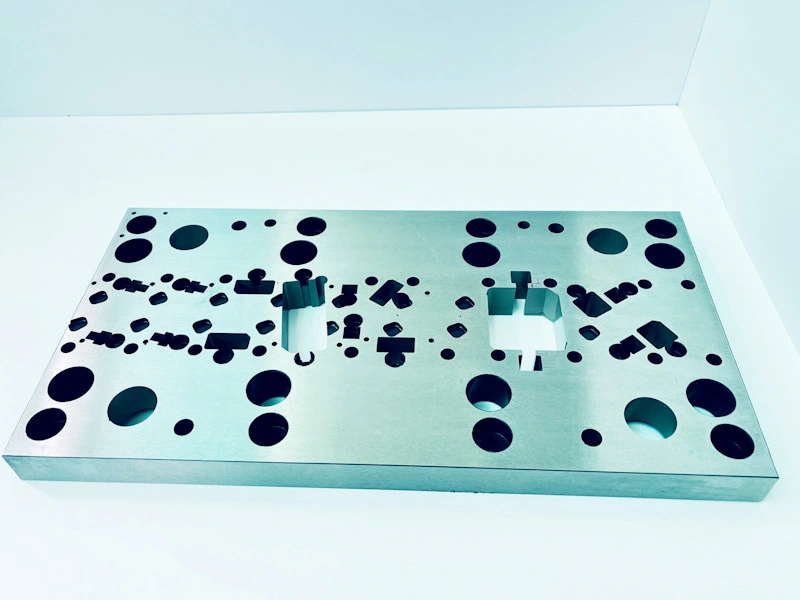

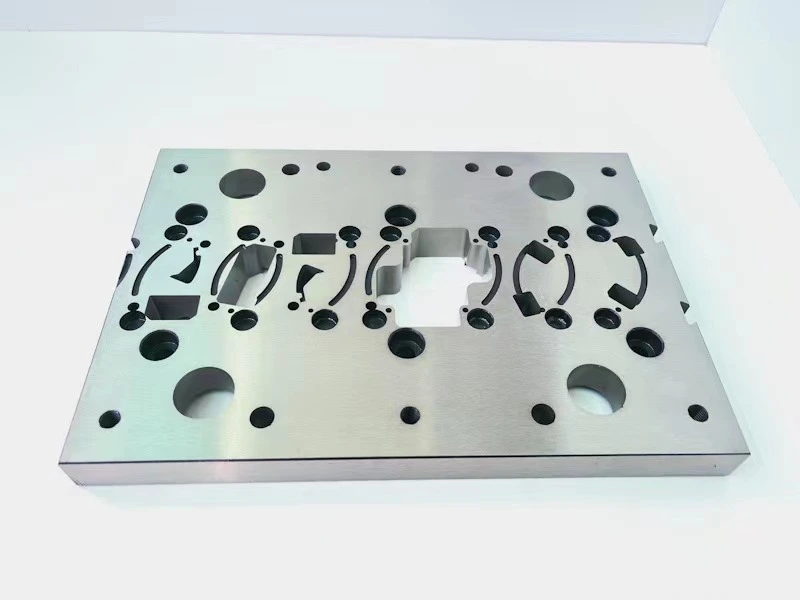

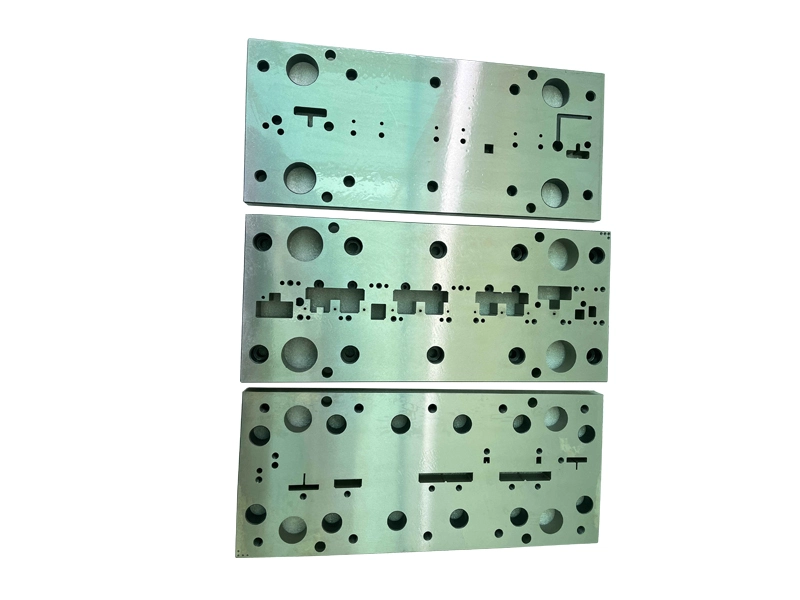

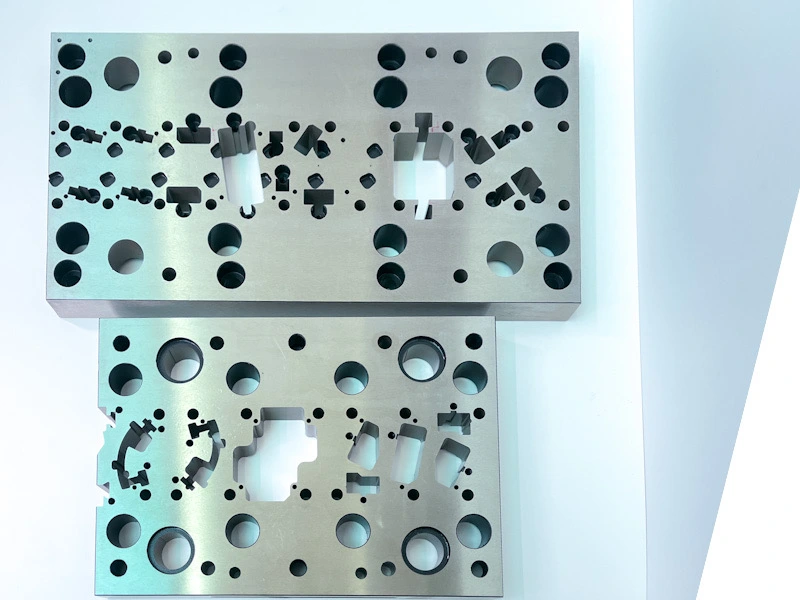

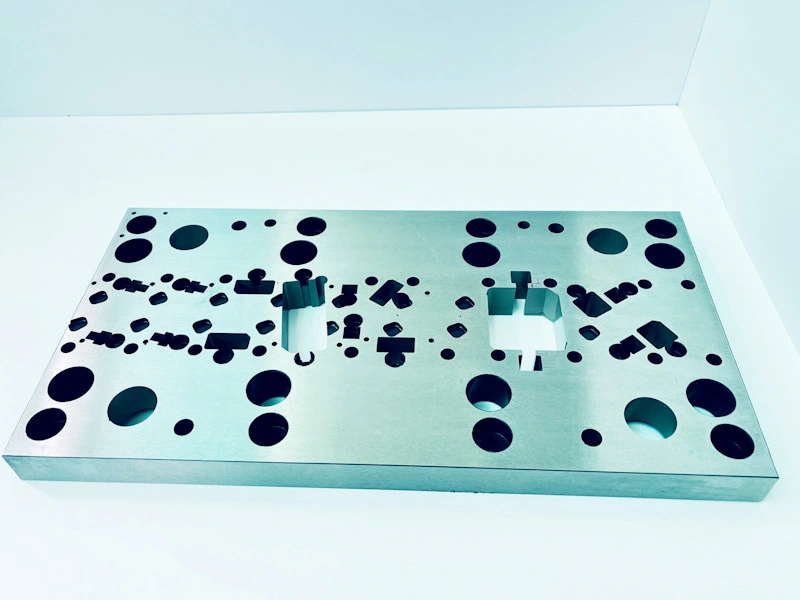

Hardware mold is in industrial production, with a variety of presses and special tools mounted on the press, through the pressure of the metal material to make the required shape of the parts or products, this special tool is collectively known as hardware mould. The shape of the mold determines the shape of these products, and the processing quality and precision of the mold also determine the quality of these products.

1. Wear resistance of hardware mould accessories

The wear resistance of the material is the basic and important performance of the mold.

Hardness is the main factor affecting wear resistance. In general, the higher the hardness of the mold parts, the smaller the wear, and the better the wear resistance.

better. In addition, wear resistance is also related to the type, number, form, size and distribution of carbide in the material.

2. High-temperature resistance of hardware mould accessories

When the working temperature of the mold is high, it will make the hardness and strength decrease, leading to early wear or plastic deformation of the mold and failure.

Therefore, the mold material should have a high tempering stability to ensure that the mold is at the working temperature, with high hardness and strength.

3. Fatigue fracture performance of hardware mould accessories

Mold work processes, under the long-term role of cyclic stress, often lead to fatigue fracture. The fatigue fracture performance of the mold mainly depends on its strength, toughness, hardness, and the content of inclusions in the material.

4. Strong toughness of hardware mould accessories

Mold is often subjected to large impact loads, resulting in brittle fractures. Mold toughness mainly depends on the material carbon content, grain size and organization state.

5. Corrosion resistance of hardware mould accessories

Some molds such as plastic mold at work, due to the presence of chlorine, fluorine and other elements in the plastic, decomposition after heat precipitation of HCI and other strong erosive gases, erosion of the mold cavity surface, increase its surface roughness, aggravate the wear loss effect.

6. Hot and cold fatigue resistance of hardware mould accessories

Mold in the work process in the repeated heating and cooling state, so that the cavity surface by the role of tensile and pressure stress, causing surface cracking and spalling, increasing friction, hindering plastic deformation, reducing the dimensional accuracy, thus leading to mold failure.

The hardware mould is composed of the following parts: mold shank, upper mold seat, guide sleeve, convex mold, pad, fixed plate, unloading plate and screws, pins, lower mold seat, guide pillar, concave mold, guide plate, bearing plate and other parts.

Let us be your resource to determine which manufacturing processes are right for your project. Start your project with a free quote.