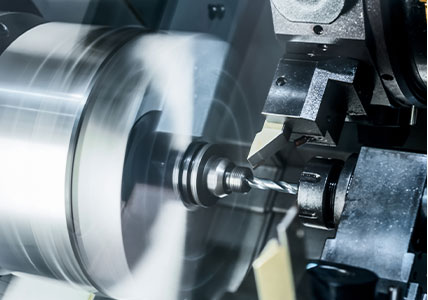

CNC turning is a precision machining process that relies on computer-generated digital blueprints. In recent years, fast development in AI CNC machining technology has made it easier than ever before to produce reliable parts, products, and tools made of metals, plastics, and even wood. Turning is an act of using a lathe, involving the use of a cutting tool to remove material from a larger workpiece. With the help of a CNC control console, human intervention during turning can be eliminated. It offers the industry a fast and reliable tool for producing customized parts with precision OEM CNC turning machining by removing unnecessary material to form the desired shape.

Accuracy: for many companies, accuracy is one of the most competitive advantages of CNC turning. By integrating CAD or CAM files into the process, machines can perform strict measurements and eliminate the waste of natural human errors. With advanced machines, experts can provide great exactitude for producing prototypes or carrying out the entire production process. Especially when accuracy is crucial, a small defect or slight deviation from tolerances is enough to cause serious damage. As the machines used are programmed, each cut is exact. In other words, the last component produced at the end of the production run is identical to the first component.

Flexibility: flexibility is another benefit of precision turning services. They have multiple-size capabilities to meet the flexibility of various applications. As the tasks performed by this machine are programmatic, changing them is relatively simple. By accessing the keyboard, machine operators can produce one component for your company and make appropriate programming changes to produce something completely different. Thus, you can rely on the same manufacturing firm or service provider to offer a large number of unique components.

Repeatability: CNC turning can provide excellent repeatability with unmatched accuracy in mass production. In this way, your enterprise can maximize production output and minimize losses, allowing you to invest your funds freely in other areas.

Safety: indeed, the operator supervising the lathe must undergo extensive training. After all, the environment with tools and machinery could pose risks of bodily harm or more severe. To ensure 100% safety, the manufacturing firm you choose will comply with strict regulations. The lathe used in CNC turning is automatic, meaning that the operator is present but not on the machine, which can reduce labor intensity. Meanwhile, the machine body is equipped with CNC turning fixture, fully enclosed or semi-enclosed protective devices to prevent flying debris from the machined product and reduce injuries to workers.