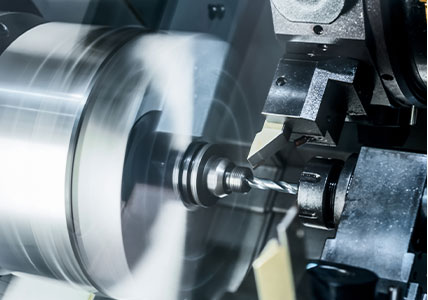

The CNC machining process involves fixing the material in the lathe and machining it by moving a single point cutting tool parallel to the axis of rotation, shaping the material. Precise measurements are input into the machine through CAD software. Once the computer reads the instructions, it controls the lathe to ensure the parts are manufactured to the exact specifications required. This differs from traditional machining as it is the workstation that rotates, not the cutting tool.

Due to their mode of operation, CNC machining is often used in manufacturing parts that are more cylindrical or elliptical in shape. This technology is also chosen before CNC milling or 3D printing as it is able to produce multiple identical components quickly from a single raw material. There are many reasons why manufacturers prefer to use computer-assisted technology over manual machining. It is not only more cost-effective, but it also increases production speed and efficiency - meaning you can produce more components in a shorter amount of time. Manufacturers also see a reduction in waste due to the higher level of accuracy provided by CNC machining, as they are able to extract more value from the raw material.

CNC machining is an extremely versatile manufacturing process. While it is primarily associated with the automotive, aerospace, and engineering industries, it can also be used to produce items such as art and decorative pieces. The most commonly created CNC machining parts can be divided into four major categories:

Metal parts: CNC machining parts made from metal are typically used in the automotive industry. Components can be manufactured using materials such as steel, brass, and aluminum.

Steel parts: CNC machining parts made from steel are highly economical and durable, although they are usually more expensive than aluminum parts. They are primarily used in the aerospace and automotive industries. Aluminum parts are mainly used for high-tech applications as the material is lightweight and strong. It also has excellent corrosion resistance, allowing aluminum to be used in multiple applications. Brass parts are associated with electrical contacts, hardware, and several other commercial products. They are easy to machine, making them very cost-effective.

Acrylic components: Modern acrylic materials are widely used in various CNC machining parts. These range from highly complex mechanical components used in microfluidic devices to company logos and signs. Acrylic can also be used for artwork and decorations in offices or around the house.

Electronic components: CNC machining can also be used for manufacturing printed circuit boards (PCBs). These components are highly effective in the electronic field due to the higher precision provided by computer-assisted manufacturing.