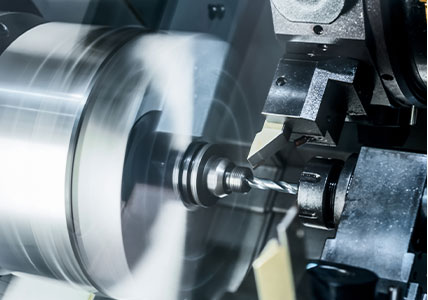

1,Install shields and safety gates to ensure that the operator does not touch the rotating parts.

2,Keep enough distance during machining to avoid being hit by rotating parts and moving parts.

3,Before using CNC milling, check that all tools and cutters are in order to avoid damage or looseness.

4,For parts that rotate at high speeds, use a balancing tool to ensure they are balanced.

5,During operation, pay attention to the operating status of the machine and stop immediately to check if abnormalities are found.

6,Operators need to wear proper personal protective equipment such as gloves, glasses and ear plugs to avoid body damage from machine debris, chips, dust, etc.

7,When cleaning the CNC machine, use specific tools and methods to avoid damage to hands or other accidents.

8,When maintaining the CNC machine, turn off the power and wait for the machine to cool down before operating it to avoid accidents such as electric shock or burns.

These are some of the safety matters that need to be noted when using CNC for precision parts machining, which need to be strictly observed by the operators to ensure the safety of themselves and the people around them.