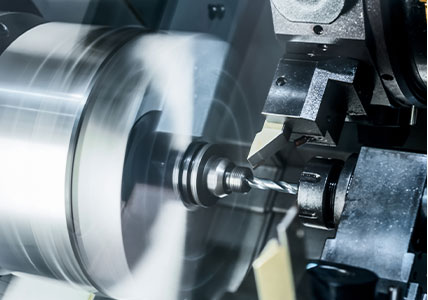

CNC precision machining is the process of cutting or removing material from a piece or pieces of material, typically metal. While there are several different methods of achieving precision, some of the most common include turning and milling. CNC precision machining is used to manufacture various tools and components used in industries ranging from aerospace to food production.

There are several reasons why CNC precision machining is highly sought after by such a wide range of industries. CNC precision machining allows for speedy production. With the ability to create hundreds or even thousands of components or tools with just the push of a button, CNC precision machining technology allows for labor to be directed towards more skilled production and service management. Investing in CNC precision machining is a great way to improve operational efficiency.

Every manufacturing process has its own unique advantages and disadvantages, and choosing the right process involves weighing these pros and cons against the requirements of the project at hand. Sometimes the choice is clear-cut: if you need a small quantity of solid metal parts with precise notches on their surface, CNC precision machining is the obvious choice.

Order volume is one of the main factors to consider when choosing a manufacturing process. Batch producing parts using a 3D printer may be impractical, just as it may be economically irresponsible to create disposable prototypes using an injection molding machine. At the same time, CNC precision machining is suitable for orders of varying scales. It offers moderate speed and cost, making it suitable for part quantities ranging from 1 to 1,000.

CNC precision machining is suitable for small orders as it does not require tooling. However, if precision and mechanical performance are not of utmost importance, small-volume parts, especially plastic ones, may be more suitable for 3D printing. On the other end of the scale, CNC precision machining is no longer economical or time-efficient at around 1,000 units. When larger production volumes are needed, mass production processes such as injection molding may be necessary.

CNC precision machining is not an extremely expensive process, but it is also not the cheapest when the expected outcome is dynamic prototypes or very basic products. Therefore, CNC should be used for prototype designs and production projects where quality is more important than the budget. If cost-saving is a top priority, it is best to use processes such as 3D printing, which can offer very low costs in small quantities, or molding processes such as injection molding, which are cost-effective in large quantities.